EziWash

Heavy Duty Alkaline Spray Cleaner

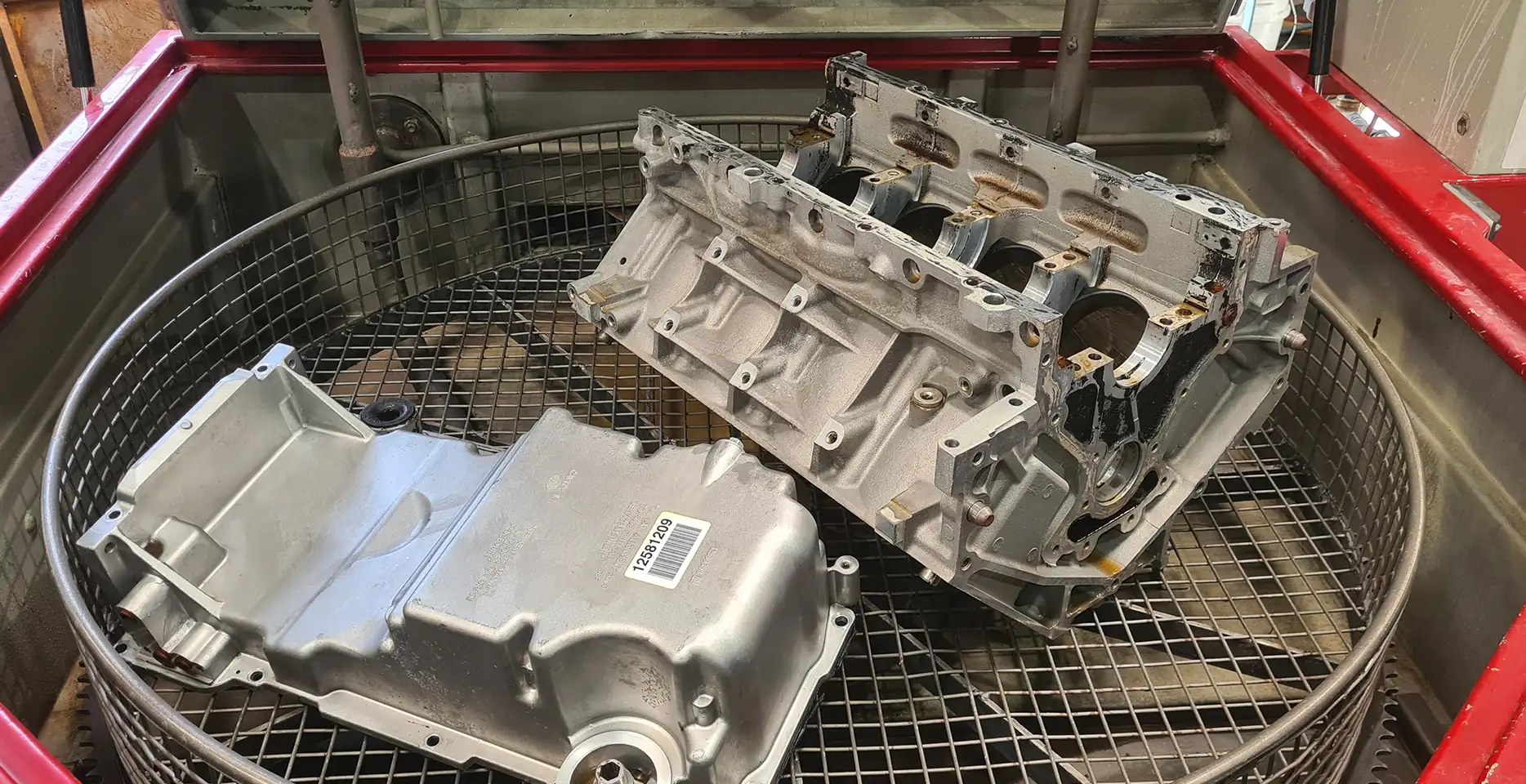

EziWash Alkaline Spray Cleaner is a cutting-edge washing compound designed for the efficient cleaning of both ferrous and nonferrous metals. EziWash is a free-flowing, light brownish powder formulated with components to prevent dusting and caking. Tailored for the metalworking and automotive industries, EziWash not only offers exceptional cleaning performance but also stands out for its rinseability. This also makes it ideal for pre-phosphating cleaning as it prevents alkaline carryover into the phosphate bath.

EZIWASH

Key Features and Benefits

Powerful Cleaning

EziWash, an effective alkaline spray cleaner, delivers heavy-duty detergency for thorough cleaning while ensuring industrial safety on all metals.

Low Foaming

It remains non-foaming even under demanding spray wash conditions, such as high pressure, low temperature, or with soft water.

Versatile Compatibility

Quick break detergent which is safe for industrial use on a wide range of metals, including aluminium, galvanized steel, and magnesium.

Efficient Rinsing

EziWash is freerinsing, leaving no residue behind.

Easy to Mix

The powder dissolves quickly, simplifying the recharging process.

Hard Water Tolerance

Can be combined with sequestering agents to effectively handle hard water conditions.

Buffered Solution

Maintains consistent cleaning effectiveness throughout the solution’s lifespan.

No Harsh Chemicals

EziWash, an advanced alkaline spray cleaner, contains no sodium hydroxide or free caustic, ensuring a safe and environmentally friendly solution.

Application Guidelines

- To prepare a solution, add EziWash to warm circulating water at a recommended dosage ranging from 10 grams to 28 grams per litre. Heat the mixture to a temperature between 60°C to 82°C for optimum performance.

- We highly recommend incorporating EziVac for your monthly machine service and restarting the machine with EziWash for continued superior results.

CASE STUDY

Maximum Efficiency: Apollo's Solution for Industrial Filter Cleaning

Join the water revolution, unleashing efficiency with Apollo Alkaline Spray Cleaner System for the Industrial Filter Cleaning Sector.

How Apollo Engineering Helps You:

Reduce wash time by

75%

Reduce water consumption by

83%

Increase Productivity by

200%

The correct equipment and chemical relationship is vital for optimum performance.

Frequently

asked

questions

Don’t see your question about EziWash answered here? Our experts are ready to help with your specific inquiries about this industrial cleaning solution. Contact our team for immediate assistance.

Why is it important to review the Safety Data Sheet (SDS) before using EziWash?

Familiarising yourself with the SDS ensures you understand and follow the correct safety procedures.

What is the recommended concentration range for mixing EziWash?

EziWash can be mixed at concentrations ranging from 10 to 28 grams per litre, with a recommended concentration of 20 grams per litre.

How do I know if the concentration of EziWash is too low?

Surface rust appearing on the machine or parts indicates a low concentration, and more EziWash should be added to the solution.

Can I use EziWash on aluminium?

Yes, EziWash is safe for use on aluminium at the recommended concentration.

How should I dispose of empty EziWash containers?

Empty EziWash containers should be rinsed and then placed in the recycling bin.

What contaminants does EziWash remove?

EziWash is specifically formulated to eliminate oil and grease, with added rust preventative properties.

Where can EziWash be used?

EziWash is designed for use in both Apollo Spray Washers and Apollo Hot Tanks.

Why is my EziWash foaming during use?

Foaming may occur if the temperature in the spray wash is too cold or if the cleaning solution is too saturated with contaminants.

How should I mix EziWash for optimal results?

Sprinkle EziWash into the running spray washer at the recommended temperature for proper mixing.

Can I mix EziWash with other products?

EziWash is formulated to be used alone; introducing non-approved chemicals may alter its characteristics.

What should I do in case of accidental spills?

Refer to the SDS for guidance on handling spills, with actions recommended based on the spill size.

Is EziWash effective in areas with different water hardness levels?

Yes, EziWash is designed to maintain its effectiveness across various water hardness conditions.

What is the shelf life of EziWash?

It is recommended to use EziWash within two years of manufacturing, storing tightly sealed containers in a cool, dry space.

Need Specialized Industrial Solutions?

Our expert team is ready to answer your questions and provide personalized assistance with your unique manufacturing and engineering challenges.