The Ultimate Guide to Choosing the Right Part Washer for Your Industry

When it comes to maintaining the efficiency and longevity of industrial equipment, investing in the right part washer can make all the difference. At Apollo Engineering, we offer a range of innovative solutions, including manual parts washers, automated spray washers, and hot tanks, each tailored to meet specific industrial needs.

Why Parts Washers are Essential

Cleaning parts manually is not only time-consuming but can also pose safety risks and lead to inconsistent results. Parts washers provide:

- Enhanced Cleaning Efficiency: Automated systems eliminate grease, grime, and contaminants faster than manual methods.

- Improved Safety: By reducing exposure to hazardous chemicals, parts washers create a safer working environment.

- Cost Savings: Automated solutions free up technicians for high-value tasks, ultimately saving labour costs.

“Each year, we saved $12,000 in manual cleaning costs by switching to Apollo Engineering’s automated solution.” – From one of our customers moving from Manual to an Apollo Automated Part Washer.

Speak to an expert

Types of Parts Washers

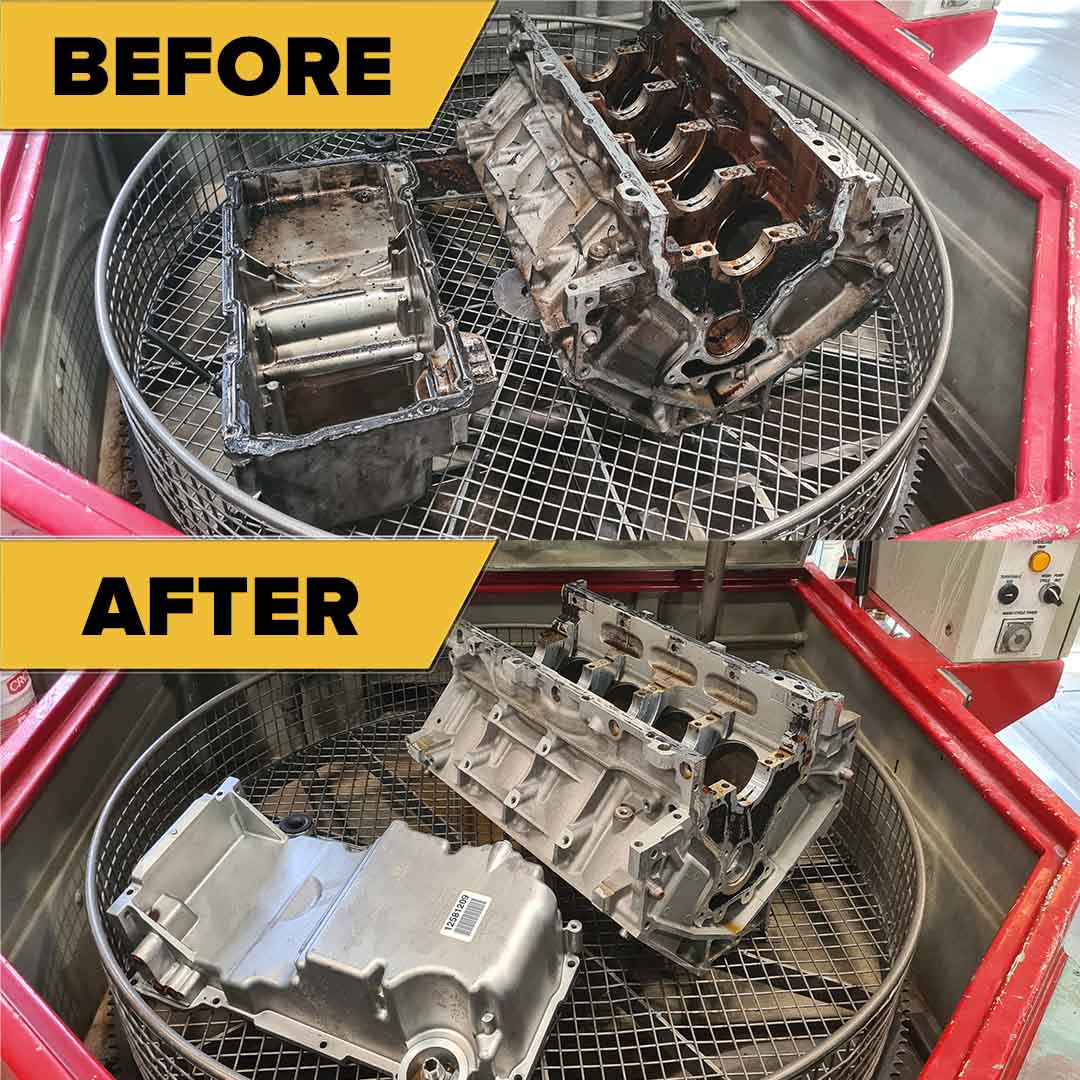

Automated Spray Washers

- Uses water-based detergents at high temperatures (up to 80°C).

- Designed for workshops handling repetitive cleaning tasks. They are ideal for cleaning heavy-duty machinery parts, automotive components, and other industrial equipment such as industrial kitchens.

- The parts undergo a robust cleaning operation with high-pressure spray from all angles as they are rotated underneath spray bars, ensuring thorough and consistent cleaning without the need for manual intervention. This process saves time and enhances safety in the workplace.

Hot Tanks

- Delivers a submersible cleaning process that reaches inside cavities and complex geometries, ensuring thorough cleaning even in hard-to-access areas.

- Commonly referred to as hot wash tanks or caustic baths, designed for cleaning engine components and heavy-duty machinery.Perfect for heavy-duty cleaning in mining, automotive, and industrial sectors.

- Submerges parts in heated, water-based chemicals with agitation to strip paint, remove carbon, and deep clean surfaces.

- Operates at high temperatures, reaching a rolling boil of up to 95°C, ensuring effective cleaning performance.

Manual Part Washer

- Utilises solvents with a recirculation system for cleaning of grease and grime.

- Requires operator control, using flexible nozzles and brush attachments for precise cleaning of intricate parts and hard-to-reach areas.

- Tailored to smaller workshops or facilities with occasional cleaning needs.

Choosing the Right Solution for Your Industry

- Automotive and Rail Overhauls: Automated spray washers are ideal for grease and oil removal.

- Mining and Heavy Equipment: Hot tanks handle large engine blocks and remove carbon, rust, and paint.

- Food Processing: Spray washers clean grease and grime from equipment used in industrial kitchens.

“We were amazed by how much we saved in chemicals and energy after upgrading to Apollo Engineering’s Hot Tanks!”

FAQ: Common Questions About Parts Washers

Hot tanks fully submerge parts in heated chemical solutions, while spray washers clean with pressurised sprays.

Yes! Apollo’s closed-loop systems minimise waste and chemical usage.

Industries like automotive, mining, rail, and food processing see significant benefits.

Yes they can, talk to us today as we have specialised chemicals to clean aluminium without damaging it.

Ready to Boost Your Workshop Efficiency?

Selecting the right parts washer can transform your operations, saving time and money while improving safety and efficiency. Contact Apollo Engineering to learn more about how our solutions can be tailored to your specific needs.