EziStrip

Heavy Duty Organic Soils and Paint Removal Additive

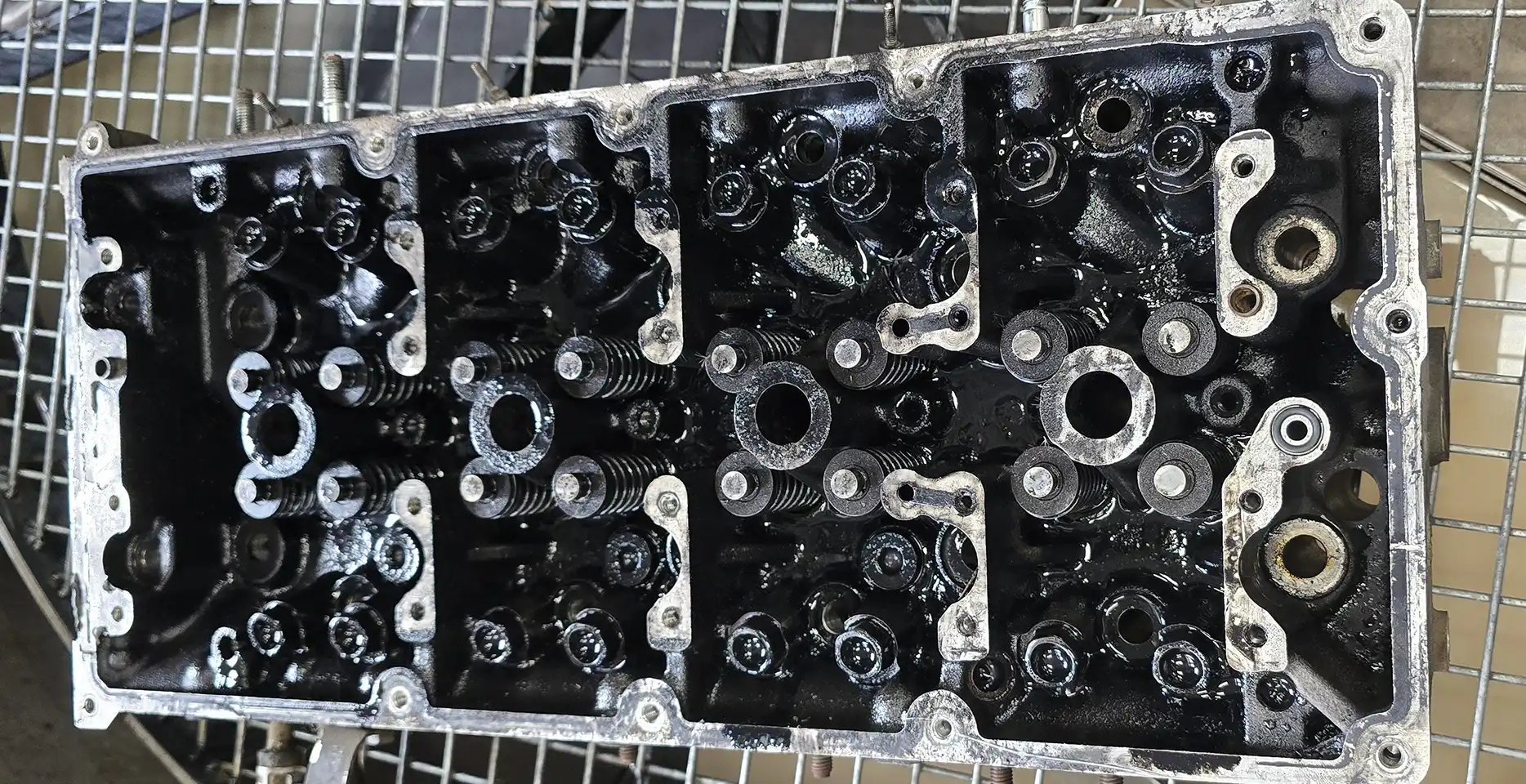

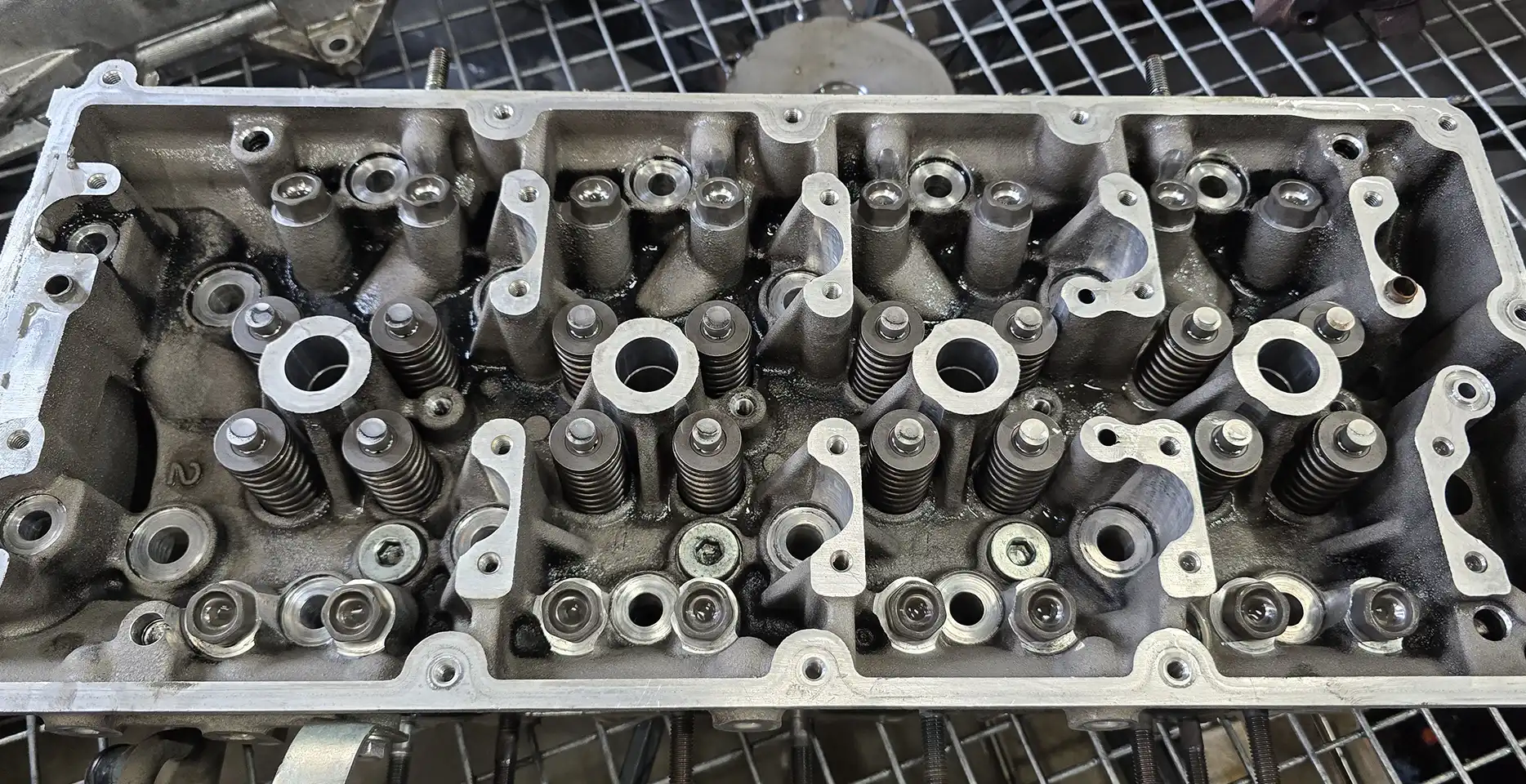

Eliminate the need for methylene chloride cold strip tanks with the Apollo EziStrip two-part cleaning and paint stripping system. EziStrip and EziWash combine to create an advanced degreaser, de-carboniser, and paint stripper with rust inhibitor technology, suitable for both ferrous and non-ferrous metals in Apollo Spray Washers and Hot Tanks.

EziWash, a light brown powder, and EziStrip, a lightcoloured solvent with a sweet odour, are specifically formulated to penetrate and remove stubborn soils and a variety of paint finishes. Experience the superior performance and safety of EziStrip additive for your most challenging cleaning and stripping applications.

EZISTRIP

Key Features and Benefits

Efficient Paint Stripping

Improved Performance

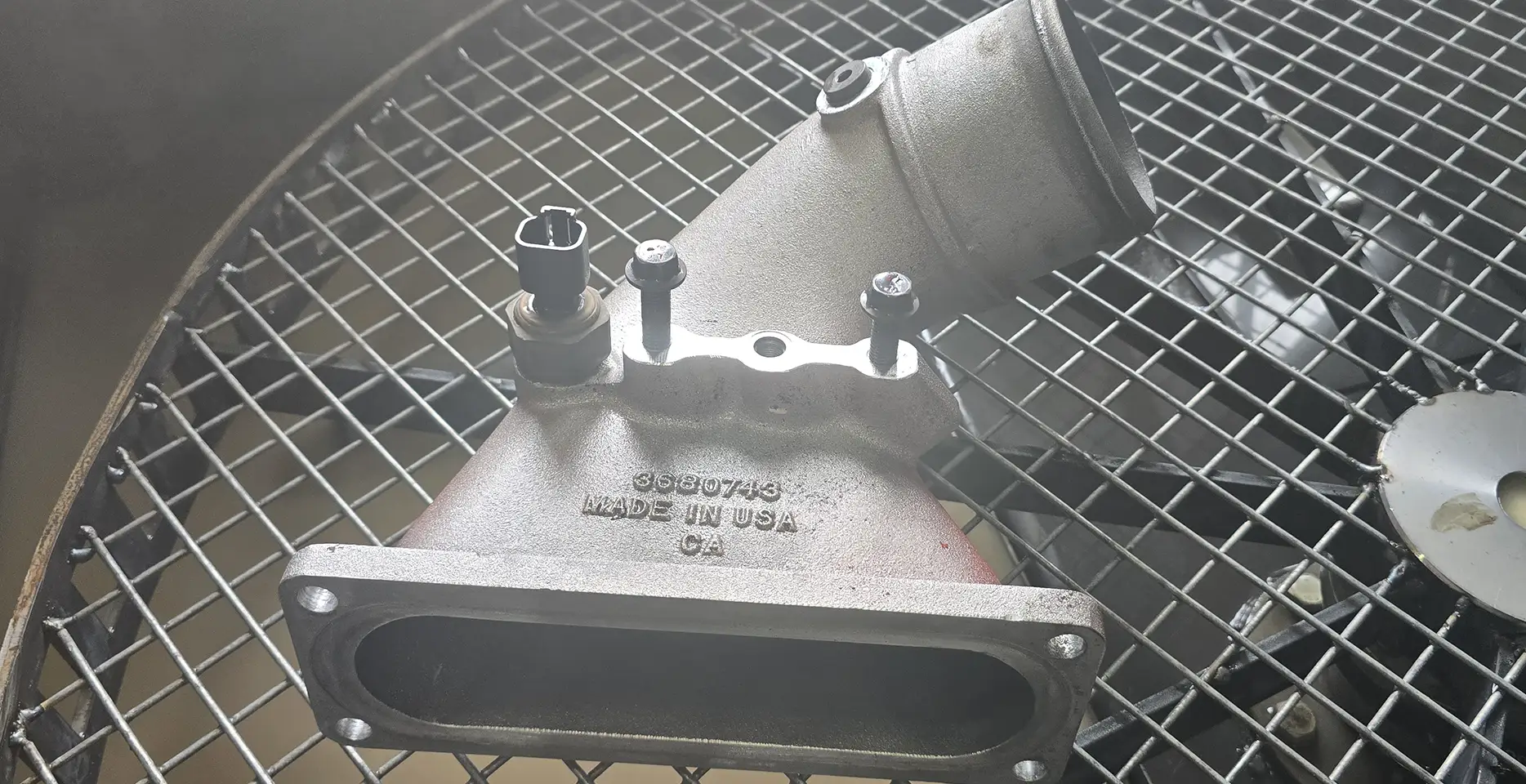

Aluminium Safe

Versatile Application

Application Guidelines

-

Recommended Concentrations:

Use EziStrip at concentration of 10% v/v of tank volume. This is in combination with Apollo EziWash at 10 to 28grams per litre. -

Temperature Range:

Maintain the solution temperature between 50-60C. -

Mixing Instructions:

EziStrip is a liquid there is no mixing required, add straight to the tank. EziWash will need to be premixed in separate bucket for Hot Tank application and added to warm circulating water for Spray Washer application. -

Caution on Non-Ferrous Metals:

EziWash and EziStrip are designed to be used on Non-Ferrous metals including steel, cast iron, aluminium, and zine. Do not use EziStrip on Magnesium. Recommended to be used in a stainless-steel Apollo Spray Washer and Apollo Hot Tank with Stainless Steel lip due to paint stripping power. -

Safety Precautions:

Exercise care to prevent skin, eye and clothing contact while handling EziWash and EziStrip.

Frequently

asked

questions

Don’t see your question about EziStrip answered here? Our experts are ready to help with your specific inquiries about this industrial cleaning solution. Contact our team for immediate assistance.

Why is it important to review the Safety Data Sheet (SDS) before using EziStrip?

Prior to using this, it is crucial to be acquainted with the Safety Data Sheet (SDS) for correct safety procedures.

What is the recommended concentration range for mixing EziStrip?

Recommended concentration 10%.

Can I use EziStrip on aluminium?

Yes, EziStrip is aluminium safe.

How should I dispose of empty EziStrip containers?

EziStrip is packaged in plastic drums. After emptying the drum, it should be rinsed and then placed in the recycling bin.

What contaminants does EziStrip remove?

EziStrip removes carbon and tough paint jobs including two pack and epoxy finishes.

Where can EziStrip be used?

EziStrip can be used in both hot tanks and spray washers, always speak with your Apollo representative before starting a new application.

Why is my EziStrip foaming during use?

If foaming occurs, it indicates contamination or improper conditions. Additionally, when mixed with EziWash, foaming can occur if the temperature is below 50°C.

How should I mix EziStrip for optimal results?

EziStrip is a liquid which can be poured directly and safely into the Apollo Hot Tank with EziWash.

Can I mix EziStrip with other products?

Yes, EziStrip can be mixed with EziWash only.

What should I do in case of accidental spills?

In the event of a spill, refer to the SDS for guidance. Different actions are recommended based on the size of the spill.

Is EziStrip effective in areas with different water hardness levels?

It is designed to maintain its effectiveness across various water hardness conditions.

What is the shelf life of EziStrip?

It is recommended to use It within two years of manufacturing. When storing the chemical on-site, ensure the lid is tightly sealed and kept in a cool dry space.

Need Specialized Industrial Solutions?

Our expert team is ready to answer your questions and provide personalized assistance with your unique manufacturing and engineering challenges.