EziClean

Ultimate Advanced Alkaline Hot Tank Cleaner

EziClean is an advanced hot tank cleaner designed for thoroughly cleaning the most heavily soiled ferrous metal components and is a game changer for engine overhaul facilities. EziClean is a quick break detergent, is non-caking so is easy to mix and provides the exceptional cleaning performance that you would expect from a technologically advanced product.

EZICLEAN

Key Features and Benefits

Highly Effective Cleaning for Ferrous Metals

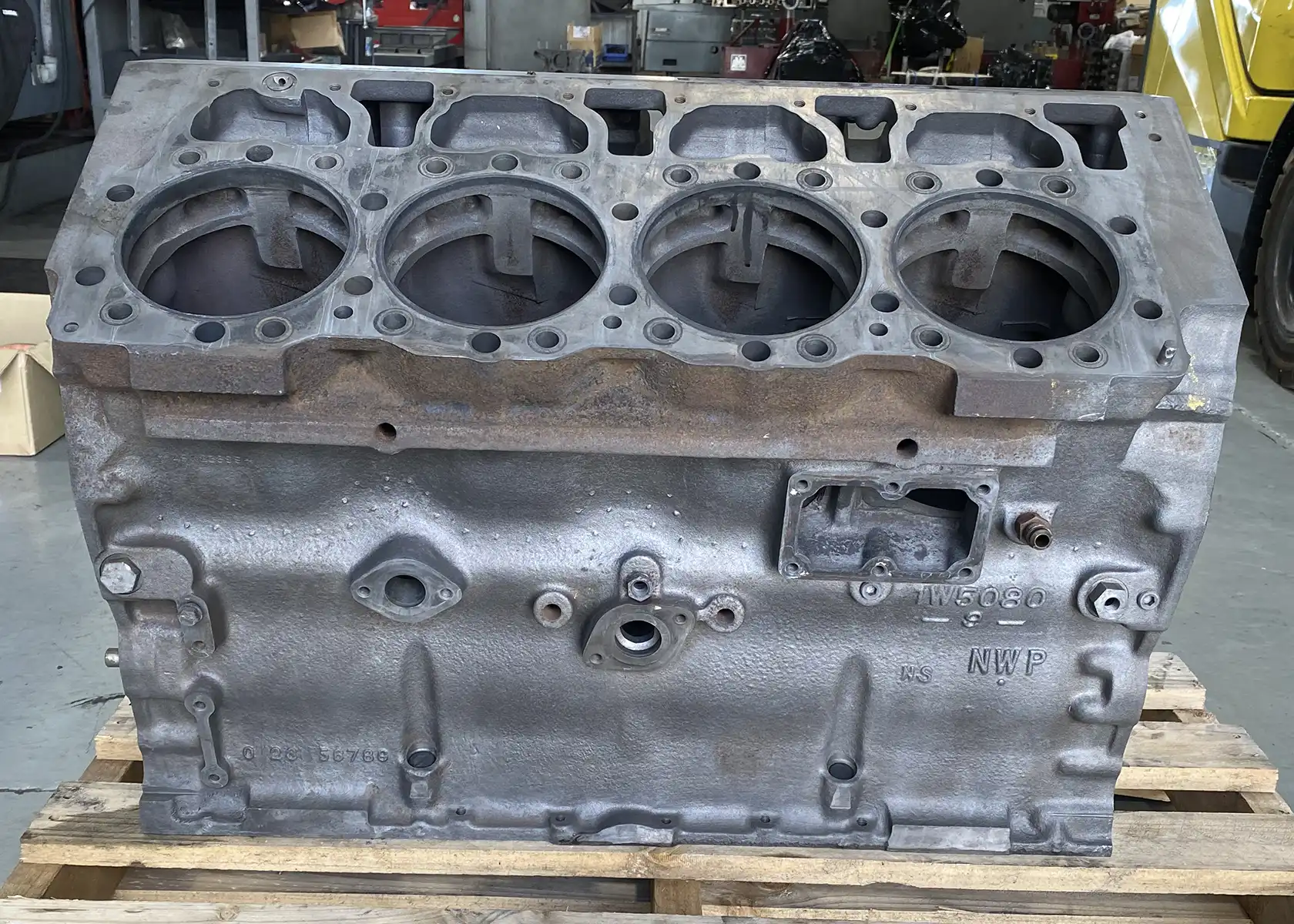

Delivers powerful cleaning for steel and copper components, including engine blocks, cylinder heads, crankshafts, gears, and housings. Not suitable for non-ferrous metals.

Quick Grease and Oil Removal

EziClean rapidly eliminates grease and oil, significantly increasing productivity.

Superior Paint Stripping

Paint stripping capabilities with no residue.

Free-Rinsing Convenience

Effortless rinsing to save water.

Consistent Cleaning Performance

Buffered solution maintains effectiveness over time.

Carbon Deposit Disruption

In an agitated solution, EziClean effectively breaks down heavy carbon deposits.

Application Guidelines

-

Recommended Concentrations:

Use EziClean at concentrations ranging from 40 to 150 grams per litre of water, with higher concentrations resulting in quicker cleaning. -

Temperature Range:

Maintain the solution temperature between 80°C to 95°C. -

Mixing Instructions:

When adding additional product, pre-mix it in a separate bucket before introducing it to the tank. -

Caution on Non-Ferrous Metals:

Do not use EziClean with non-ferrous metals such as aluminium or tin. -

Safety Precautions:

Exercise care to prevent skin, eye, and clothing contact while handling EziClean.

CUSTOMER REVIEWS

Powerful engine cleaning results

We recently introduced the new Apollo Cleaning chemicals (EziClean and EziBoost) into our existing Apollo Hot tank, and the results have been outstanding. The system delivers exceptional cleaning performance, removing carbon, rust, paint, grease, and oil from engine blocks. The time-saving efficiency and reduction in manual labour have significantly boosted our productivity.

The cleaning system is cost-effective and is easy to use. The Apollo hot tank’s versatility allows us to clean various types of parts with ease. Overall, we are extremely satisfied with this new cleaning solution and highly recommend it.

Regards

Paul Bedford

Engine Reconditioning and Engineering

Frequently

asked

questions

Don’t see your question about EziClean answered here? Our experts are ready to help with your specific inquiries about this industrial cleaning solution. Contact our team for immediate assistance.

Why is it important to review the Safety Data Sheet (SDS) before using EziClean?

Prior to using EziClean, it is crucial to be acquainted with the Safety Data Sheet (SDS) for correct safety procedures.

What is the recommended concentration range for mixing EziClean?

EziClean can be mixed at concentrations ranging from 70 to 150 grams per litre. For optimum performance, we advise using 120 grams per litre. EziClean can be used at temperatures between 80°C-95°C.

Can I use EziClean on aluminium?

EziClean is not safe for use on aluminium.

How should I dispose of empty EziClean containers?

EziClean is packaged in plastic pails. After emptying the pail, it should be rinsed and then placed in the recycling bin.

What contaminants does EziClean remove?

EziClean is specifically formulated to eliminate oil and grease. It includes a built-in rust preventative to keep parts rust-free indoors between processes. Note: EziClean is not intended as a long-term rust preventative.

Where can EziClean be used?

EziClean is designed for use in both Apollo Spray Washers and Apollo Hot Tanks.

Why is my EziClean foaming during use?

EziClean can be titrated to work out the concentration.

How should I mix EziClean for optimal results?

We recommend mixing EziClean with water prior to adding to the hot tank ensuring all EziClean is dissolved prior to adding to the hot tank. Remember always add EziClean to water.

Can I mix EziClean with other products?

Yes, EziClean is formulated to be used with EziBoost if requiring a paint stripping boost.

What should I do in case of accidental spills?

In the event of a spill, refer to the SDS for guidance. Different actions are recommended based on the size of the spill.

Is EziClean effective in areas with different water hardness levels?

Yes, EziClean is designed to maintain its effectiveness across various water hardness conditions.

What is the shelf life of EziClean?

It is recommended to use EziClean within two years of manufacturing. When storing the chemical on-site, ensure the lid is tightly sealed and kept in a cool dry space.

Need Specialized Industrial Solutions?

Our expert team is ready to answer your questions and provide personalized assistance with your unique manufacturing and engineering challenges.